On May 6 2014, an article published in Métro by Johnson Maxime, painted the portrait of manufacturing process at Hewett Packard for recycling ink cartridges.

Reading the article, one might wonder if there is a better way to recycle ink cartridges than the methodology employed by HP. That is why it is important to understand the differences between traditional recycling, the method used by HP, and recycling by remanufacturing, or reuse. The latter is a greener alternative that deserves more recognition.

Thermodynamics in Recycling

There is a thermodynamic function called EXERGY, or available energy, which represents the energy difference between a situation, or material, and the environmental threshold. This is the variable that is used to study ecological life cycles, for example.

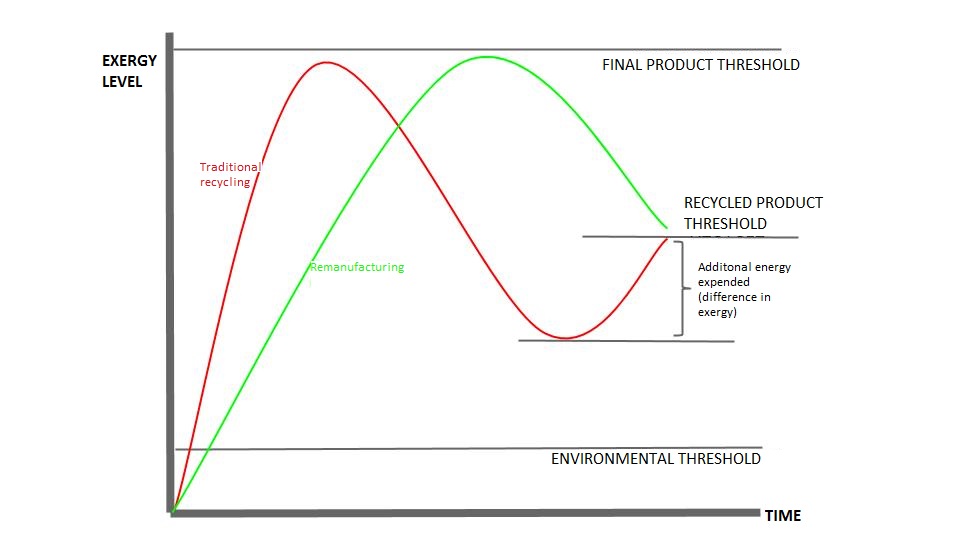

Traditional recycling procedures utilize complex physicochemical transformations to increase the product’s internal energy threshold. These processes fundamentally change the basic threshold of the raw materials that comprise the product. In traditional recycling, the final product must have a very high level of exergy, but after the transformation, the remaining materials have little exergy, so new raw materials must be used. This practice causes a significant loss of exergy as we approach the environmental threshold. Then, to compensate for this loss, complex operations must be realized to increase the quality of the final product. Recycling by remanufacturing or reuse preserves most of the energy, avoiding the wasted energy reconverting materials. Thus, traditional recycling methods remain cheaper than the manufacture of new products, but less profitable and less environmentally friendly than remanufacturing or reuse.

And in practice?

The following diagram illustrates what has been explained above. It can be applied broadly to all manufactured products; we’ll use an ink cartridge for example. In both types of recycling, at the beginning of the production chain, all the raw materials used share the same environmental threshold. Then, transformation processes occur to increase the level of exergy to the threshold of the final product. It is here that the difference between recycling methods becomes crucial.

In a traditional recycling, the cartridge is demolished to recover the molten materials to start the process anew. However, these materials contain impurities, so you have to add new raw materials to be processed, which considerably reduce the level of exergy. Then a lot of energy must be deployed to stabilize the threshold of the recycled product.

In a process of remanufacturing or reuse, this whole sequence which causes additional energy consumption does not exist. The cartridges are disassembled, cleaned, reassembled and filled. This avoids repeating the complex processes of melting and molding the cartridges. Thus, less energy is used making this the ultimate environmentally-friendly method.

Table 1: Changes in the level of exergy over time for each type of recycling

Basically, the remanufacturing or reuse process reaches the same result as recycling, with fewer steps and, therefore, less energy expended.

Réponse/Reply

Commentaires/Comments