In this series of articles, we will explain the properties of the various materials that are used by 3D printers along with how to use them to get the best results. If you are not familiar with 3D printers or would like to know more, check out our article on how 3D printers work.

PLA

PLA is one of the two most commons thermoplastics use in FDM 3d printing. PLA stands for Polylactic Acid and, as the name shows, it is made out of lactic acid. This is manufactured by transforming dextrose, a naturally occuring sugar that is extracted from sugar rich plants such as corn, sugarcane or beets. This allows this bio-plastic to be the most ecologically friendly material for 3D printers; it is produced from renewable materials and biodegrades in industrial or hot compost piles. Its creation also emits about 68% less greenhouse gases than that of petroleum based plastics. Since PLA is sugar based the emanations produced by melting it are non-toxic and have a pleasant sweet smell.

PLA is one of the two most commons thermoplastics use in FDM 3d printing. PLA stands for Polylactic Acid and, as the name shows, it is made out of lactic acid. This is manufactured by transforming dextrose, a naturally occuring sugar that is extracted from sugar rich plants such as corn, sugarcane or beets. This allows this bio-plastic to be the most ecologically friendly material for 3D printers; it is produced from renewable materials and biodegrades in industrial or hot compost piles. Its creation also emits about 68% less greenhouse gases than that of petroleum based plastics. Since PLA is sugar based the emanations produced by melting it are non-toxic and have a pleasant sweet smell.

Because of its properties and the fact that, inside the human body, PLA degrades into harmless lactic acid over a period of 6 months to 2 years, PLA is often used to make medical implants. It is also used to make biodegradable food containers.

On the mechanical level, PLA is rigid and has a very low level of flexibility this, it can break if exposed to strong forces.

PLA in 3D printing

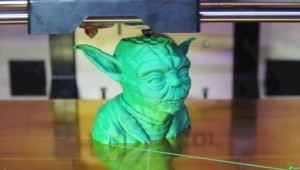

PLA extrusion

PLA extrusion

The PLA for use in 3D printers is generally sold in spools of 1kg. It is available in a variety of colours and can be bought at most if not all 3D printing material suppliers. Although this plastic starts softening around 60°C and melting at about 160°C, the required extrusion temperature is usually between 180 and 220°C. Your supplier should provide you with a more precise temperature range. Our PLA filament for example, must be extruded between 190 and 220°C. This thermoplastic is the least heat resistant material used in 3D printing, as such, it is not recommended for use in parts that will be close to heat sources such as hotend holders.

Printing surface for PLA

This bio-plastic is very dimensionnally stable, this means that it does not warp or shrink when it’s cooling. This eliminates the need for a heated print bed. The most commonly used bed material is glass covered with blue painter’s tape. The painter’s tape is there to add some friction and allow the melted plastic to stick to it instead of sliding across the glass. It is very important to apply the tape as flat as possible in order to avoid deformatins in the printed piece. Regular masking tap can also be used, but it has proven to be less suited for the job than blue painter’s tape.

It is also possible to print directly on the glass plate, but this can cause problems with the first layer not sticking properly. This can be attenuated by heating the glass bed to 60 or 70°C.

A Polycarbonate (Lexan) sheet lighlty coated with oil can also be used as the print bed. It can be difficult to remove the printed part if there wasn’t enough oil or if the hotend was too close to the surface. As such, polycarbonate is a possible alternative, but it has no significant advantage over blue painter’s tape that outweigh the risk of your printed piece sticking to the sheet.

Other less common methods have been tested by the RepRap community; you can see the results here.

How to properly store PLA filament

How to properly store PLA filament

PLA is hygroscopic, it tends to absorb or release humidity in order to be in balance with its surroundings. Leaving it in a humid room can cause problems. A filament containing too much moisture can produce bubbles and water vapor when it is extruding, this reduces precision and quality in the finished part. To avoid this kind of problem, it is recommended to store PLA in a sealed container with rice, silica gel or another moisture absorbing material if you linve in a humid climate. This method can also be used to dry filament over a long period of time. Faster drying can be acheived by butting the filament on a piece of aluminium foil in the oven at the lowest possible temperature (never go over 80°C-176°F, but you can go as low as 40°C-104°F to be safe and make sure the PLA doesn’t stick to itself). After about an hour, your filament should be sufficiently dry. It may have stuck to itself an little, but carefully flexing it should solve this. It is important to remove the PLA filament from the spool before putting it in the oven; the spool is not made out of heat-resistant plastic and could melt in the oven, thus ruining your material.

Be carfeul when storing PLA plastic at low temperature. It is already quite rigid and it loses even more flexibility when cold. To avoid breaking your nice long spool, it is recommended to store it at room temperature or to let it slowly heat up if it has been exposed to the cold.

Remember, you can now buy your PLA on our online store.

Réponse/Reply

Commentaires/Comments