With the advent of affordable 3D printers, such as the Makerbot Replicators, 3D printing is becoming a hot subject. the rising popularity of maker communities and of DIY has given birth to the Reprap project. This is a project that aims to create a large variety of open source self-replicating 3D printers. The large variety of models that exists allow users to select one that fits their needs and budgets and thus helps spread 3D printing in homes. These Reprap 3d printers can be built at home form self-sourced parts or from kits. Some of these 3D printers can even bought pre-assembled for the less technically-inclined.

How the 3D printer works

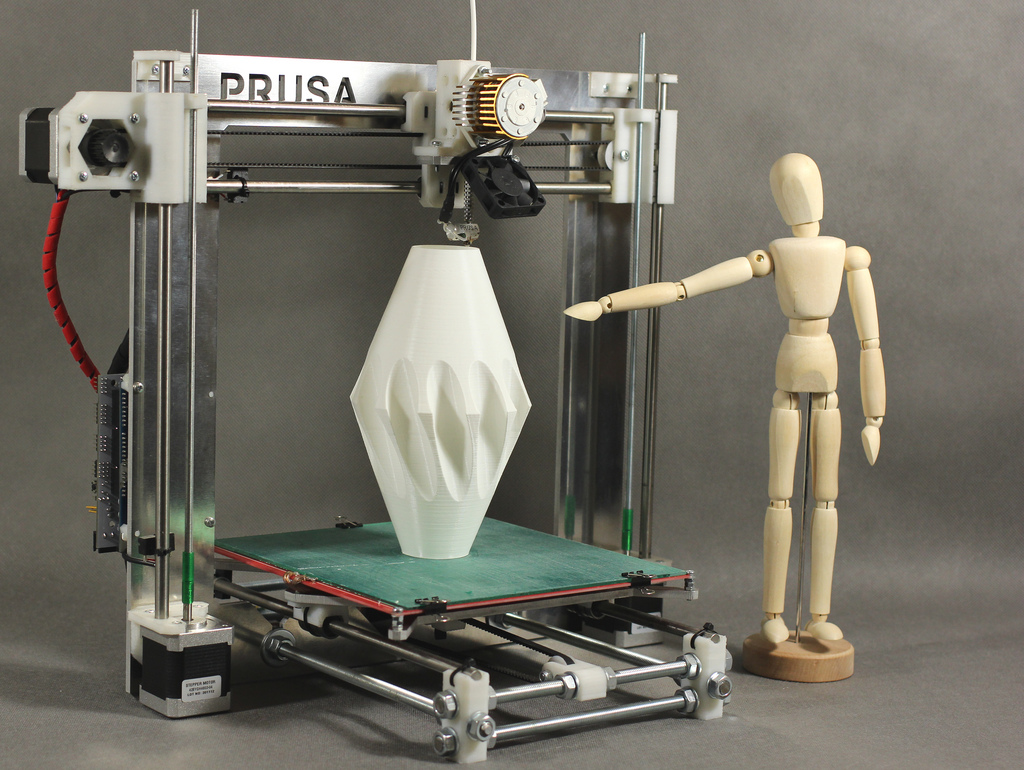

What we commonly call 3D printers use fused deposit modeling. This additive manufacturing process works by laying molten plastic layer by layer to create an objets. To achieve this, an extruder and a motor move plastic filament toward the hot printhead wich melts it to layer it on the bed, which can be heated or not depending on the type of plastic used. A large variety materials can be used and there exists a surprisingly large number of different 3D printers, but the basic process is the same for all of them, both commercial machines such as the Makerbot Replicator and Repraps like the Prusa i3.

Réponse/Reply

Commentaires/Comments